In Bangladesh, where the air ranks among the most polluted on Earth, an unexpectedly simple solution is proving that sometimes the most effective environmental interventions don't require cutting-edge technology or massive investment. A new study published in Science reveals that something as straightforward as changing how bricks are stacked in kilns could dramatically reduce the country's devastating air pollution while simultaneously increasing profits for kiln owners.

The Smoke That Shrouds a Nation

During the dry winter months, Bangladesh's skyline transforms as thousands of brick kilns begin operation. More than 8,000 smokestacks release dense plumes of black smoke into the air, contributing between 10-40% of the country's dangerous particulate pollution. These tiny particles penetrate deep into the lungs and bloodstream, causing a host of health problems from respiratory diseases to stroke and even cognitive issues.

"It's a lot of black smoke, impacting the workers and nearby villagers, but also the overall air quality of the region," explains Sameer Maithel, an engineer with Greentech Knowledge Solutions and one of the study's authors.

The sheer scale of the industry makes this pollution source particularly challenging. Bangladesh produces nearly 30 million bricks annually, with over 90% coming from these loosely regulated, coal-burning kilns. As the country rapidly urbanizes, demand continues to grow, making bricks the literal and figurative building blocks of Bangladesh's development.

Why Traditional Kilns Persist

Despite their environmental impact, traditional brick kilns remain the dominant production method in Bangladesh for several compelling reasons. Modern, high-tech kilns that produce substantially less pollution are available but come with a prohibitive price tag—up to 25 times more expensive to build and operate.

"It's quite simple and inexpensive to set up traditional-style brick kilns, so they've just proliferated," notes Nina Brooks, a global health researcher at Boston University who contributed to the study.

The traditional kiln process follows a straightforward pattern: clay bricks are molded using wooden boxes, sun-dried, and then stacked by the hundreds of thousands in a firing chamber where they're covered with ash. Workers then shovel massive amounts of coal to fire the bricks, hardening them into the construction materials that build Bangladesh's growing cities and infrastructure.

Each kiln can employ up to 200 workers who bear the brunt of the pollution. One study found nearly 80% of kiln workers report respiratory problems. But the impact extends far beyond the worksite, as kilns are often located near population centers, adding significantly to urban smog.

The Zigzag Solution

After decades of working with brick kiln owners in India, Maithel had noticed some questionable practices that compromised efficiency. Many kiln operators pack bricks too tightly, restricting oxygen flow essential for efficient burning. This tight spacing also prevents hot coals from falling to the bottom of the stack, resulting in unevenly fired bricks—some overbaked, others undercooked.

Additionally, workers typically shovel coal in bursts, working in small teams that take breaks together. This creates uneven fueling patterns that further reduce efficiency.

As an energy systems engineer, Maithel recognized that simple changes could make a significant difference. His team proposed two straightforward interventions:

- Stacking bricks in a zigzag pattern to increase airflow

- Ensuring coal gets delivered more consistently throughout the firing process

"The better you are able to provide fuel and air mixing, the probability of black smoke will be less," Maithel explained.

To test these simple interventions, the research team conducted an extensive experiment involving 276 kilns. They divided kiln owners into three groups: one received training on implementing the new methods, another got the same training plus information about potential cost savings, and a control group received no training.

Dramatic Results

The results were remarkable. Kilns that adopted the new measures saw fuel use drop by approximately 23 percent. The researchers estimate this would reduce carbon dioxide and particulate matter emissions by about 20%—a significant improvement for air quality.

"We showed that simple, low-cost interventions can really reduce pollution," said Mahbubur Rahman, an environmental health researcher at the International Centre for Diarrhoeal Disease Research, Bangladesh, who participated in the study.

The benefits extended beyond environmental improvements. Kiln owners saved nearly $40,000 each over a season due to reduced fuel consumption. Brick quality also improved, creating another economic incentive to maintain the new practices.

In fact, the economic benefits proved so compelling that a year later, kilns that had adopted the new practices were still using them—a critical factor for long-term sustainability of any environmental intervention.

A Model for Practical Environmental Solutions

What makes this study particularly significant is how it balances environmental benefits with economic reality. In developing regions where businesses operate on thin margins, environmental interventions that hurt profitability rarely succeed long-term, regardless of regulations or enforcement.

"This is wonderful evidence of how simple low-cost interventions can have a big impact on energy use," said William Checkley, an epidemiologist at Johns Hopkins University who wasn't involved in the study. "If we can implement these, we could have a significant impact in energy use and emissions, improving air quality throughout southeast Asia."

The approach demonstrates principles that could apply to numerous environmental challenges in developing economies:

- Practicality: Solutions must be implementable with existing resources and skills.

- Economic Viability: Environmental improvements should create financial benefits when possible.

- Cultural Appropriateness: Interventions must respect existing business practices and social structures.

- Scalability: Solutions should be easily replicated across thousands of similar operations.

The Path Forward

While the results are promising, significant challenges remain. To make a substantial dent in Bangladesh's air pollution, many more of the country's 8,000+ kilns need to adopt these practices. The research team, which includes scientists from the U.S., India, and Bangladesh, is now collaborating with the Bangladeshi government to expand training programs nationwide.

Regulatory issues also persist. Despite existing regulations on kiln locations, the study found that 77% of brick kilns operate illegally close to schools. Better enforcement of existing environmental standards, combined with these efficiency improvements, could multiply the air quality benefits.

For the millions of Bangladeshis who breathe some of the world's most polluted air daily, these simple changes to brick production represent a rare piece of good news. While high-tech solutions and stringent regulations have their place, this study demonstrates that sometimes the most effective environmental interventions are the simplest.

"It's a hopeful story," Brooks concludes, "of a place where solutions are quite feasible."

In a world where environmental challenges often seem overwhelming and solutions prohibitively expensive, Bangladesh's brick kilns offer an important reminder: sometimes, the most effective way to clear the air is to simply rearrange the bricks.

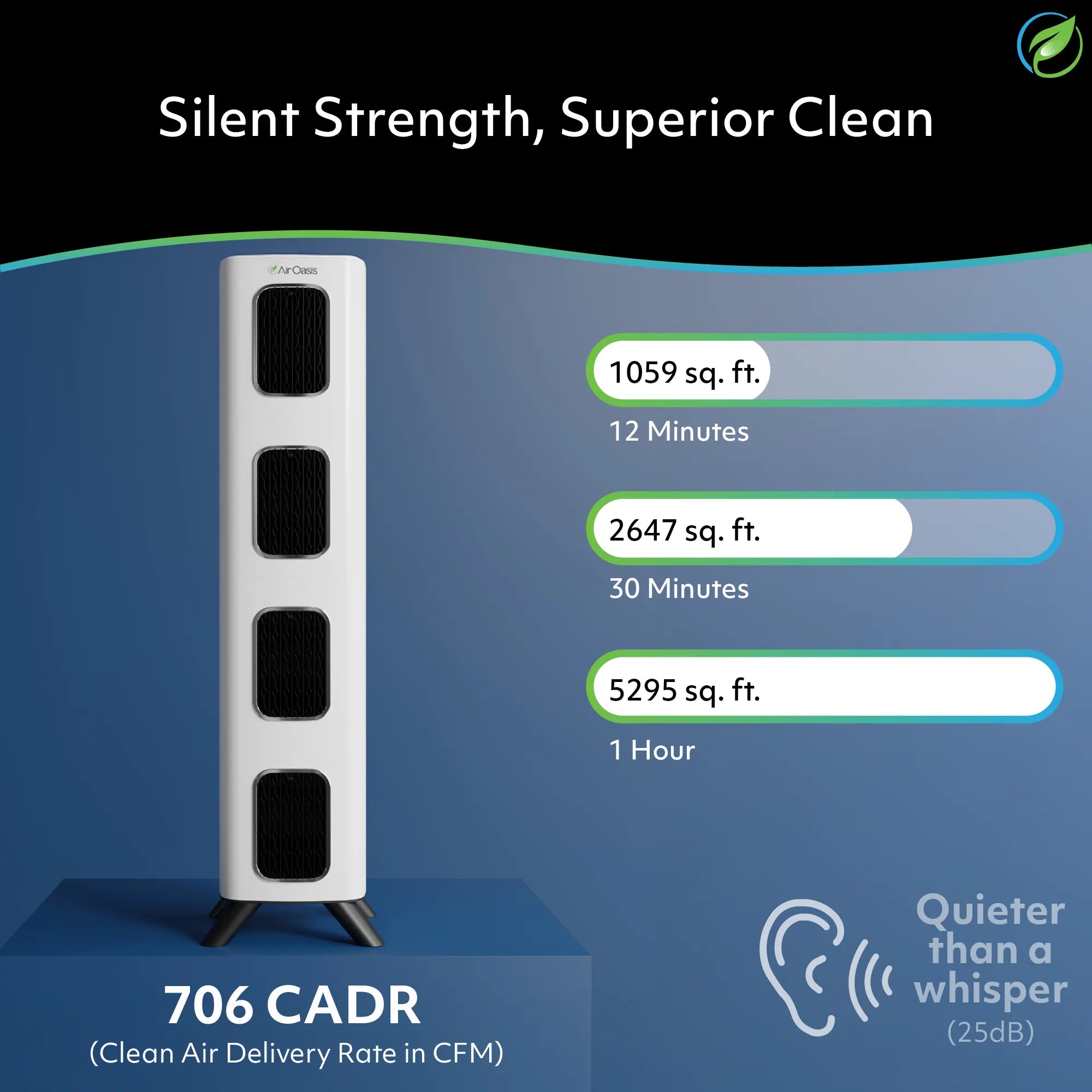

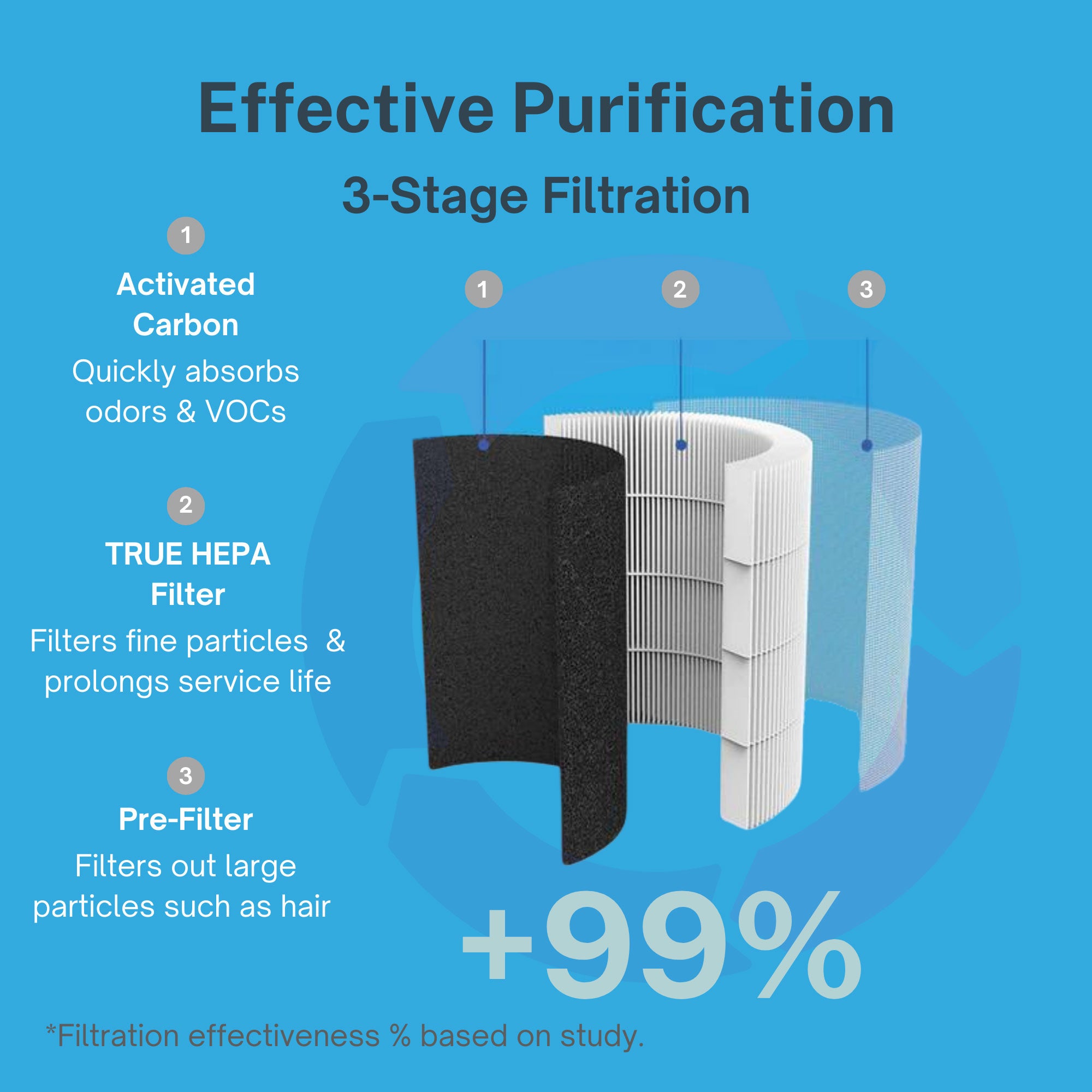

Shop Air Oasis today to bring similar air quality improvements to your own home environment through advanced air purification technology.